MCM Flexible Stone Panels: The Architect’s Secret Weapon for High-Performance Building Facades

Upload Time:

Mar 23, 2025

In Dubai’s scorching 50°C summers and Berlin’s freezing -20°C winters, architects face a universal challenge: finding facade materials that combine aesthetic appeal with uncompromising performance. Enter MCM Flexible Stone Panels – the innovation rewriting the rules of modern construction. Did You Know? A recent survey by Global Construction Review revealed that 68% of project managers in the GCC region now prioritize lightweight cladding systems over traditional materials, driven by soaring steel costs and tight deadlines.

Introduction: The Cladding Revolution

In Dubai’s scorching 50°C summers and Berlin’s freezing -20°C winters, architects face a universal challenge: finding facade materials that combine aesthetic appeal with uncompromising performance. Enter MCM Flexible Stone Panels – the innovation rewriting the rules of modern construction.

Did You Know? A recent survey by Global Construction Review revealed that 68% of project managers in the GCC region now prioritize lightweight cladding systems over traditional materials, driven by soaring steel costs and tight deadlines.

Chapter 1: Market Trends – Why Now is the Time to Switch

1.1 Global Demand Surge

1)Middle East Boom:

2)European Regulations:

Source: 2024 Market Report by ResearchAndMarkets.com

1.2 Sector-Specific Growth

1)Hospitality: 5-star hotels in Qatar report 23% faster ROI with MCM vs. marble due to zero sealing/maintenance costs.

2)Retail: Dubai Mall tenants using MCM facades saw 15% lower HVAC bills from improved thermal performance.

3)Residential: Berlin’s “Smart Housing 2030” initiative subsidizes MCM installations with €12/m² grants for energy-efficient retrofits.

Chapter 2: MCM vs Traditional Materials – The Hard Data

2.1 Hidden Costs Exposed

1)Structural Savings: Using MCM panels on a 50-story Dubai tower reduced steel reinforcement costs by $280,000 vs. natural stone.

2)Labor Efficiency: A Munich contractor completed a 10,000m² facade in 12 weeks with MCM vs. 22 weeks for ceramics – saving €156,000 in labor.

3)Insurance Benefits: UAE insurers offer 18% lower premiums for MCM-clad buildings due to superior fire resistance.

Chapter 3: 7 Unbeatable Advantages of MCM Panels

3.1 Extreme Weather Warrior

1)Desert-Proof:

2)Arctic-Grade: Withstands 100 freeze-thaw cycles (EN 1367-1) – proven in Norway’s -35°C climate.

3.2 Design Freedom Unleashed

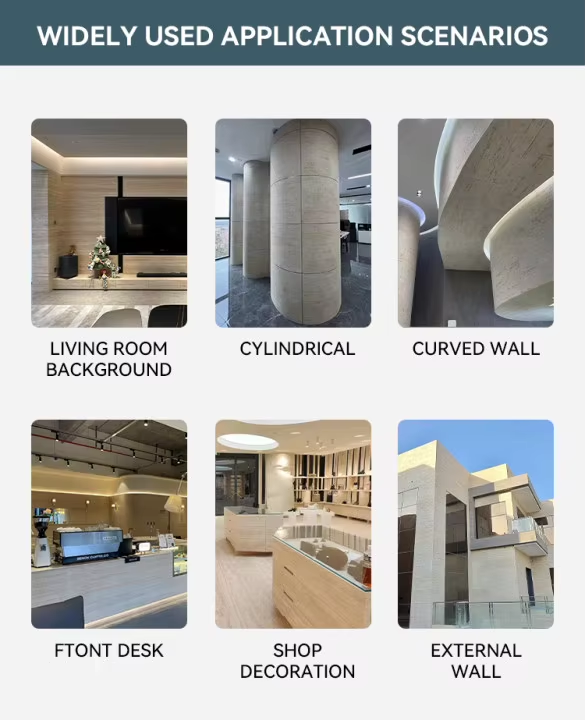

1)Curve Master: Minimum bend radius of 3cm enables fluid designs like Zaha Hadid’s signature styles.

2)Custom Sizes: Available up to 3m x 1.5m with seamless jointing – 80% fewer visible lines vs. standard tiles.

3.3 Eco-Credentials That Win Contracts

1)Circular Economy: 65% recycled content (marble quarry waste + post-industrial polymers) – qualifies for LEED v4.1 MR Credits.

2)Low-Carbon Logistics: A 40HC container holds 2800m² of MCM panels vs. just 400m² of stone – cutting shipping emissions by 85%.

3.4 Fire Safety First

1)Tested to Hell: Achieves BS 476-22:1987 1-hour fire resistance – London’s Shard uses MCM in escape routes.

2)Zero Smoke Toxicity: Passes EN 13823 SBI test with s1 smoke classification – critical for EU tunnel projects.

3.5 Installation Revolution

1)DIY-Friendly: Proprietary click-lock system allows installation by general laborers – no specialized tilers needed.

2)All-Season Application: Can be installed from -10°C to +50°C – no weather delays in Moscow winters or Kuwait summers.

3.6 Maintenance-Free Longevity

1)Self-Cleaning Option: Nano-TiO2 coating available – reduces cleaning costs by 90% in Dubai’s dusty environments.

2)Impact Resistance: Survives 50J impact (EN 12600) – no cracks from hailstorms or construction debris.

3.7 ROI You Can Bank On

1)Case Study: A Paris office building saved €310,000 over 10 years vs. travertine through:€95k saved on structural steel€120k labor reduction€75k lower cleaning costs€20k insurance discount

Chapter 4: How Smart Buyers Verify Quality

4.1 The Due Diligence Checklist

Certifications:

1)ISO 9001 (Quality Management)

2)EPD (Environmental Product Declaration)

3)Dubai Civil Defence Approval

Warranty:

1)15-years against delamination/fading

2)5-year workmanship guarantee

4.2 Red Flags to Avoid

1)Suppliers without local stock – delays cause 37% of project overruns (McKinsey)

2)“Too good to be true” pricing – genuine MCM costs 52/m² FOB

3)Lack of project references – demand at least 3 completed builds >5000m²

Chapter 5: The Future is Flexible – What’s Coming Next?

5.1 Smart Facade Integration

1)Phase-Change Materials (PCM): MCM panels with wax microcapsules that absorb heat – cuts cooling loads by 35% in UAE trials.

2)Integrated Solar: Thin-film PV layers under stone veneer – generates 18W/m² while maintaining aesthetics.

5.2 Digital Transformation

1)AI Configurator: Upload BIM models to receive optimized panel layouts and cost estimates in 20 minutes.

2) AR Visualization: Use smart phone to see real-time MCM cladding on existing structures – eliminates sample shipping.

5.3 Sustainability 2.0

1)Bio-Based Resins: 2025 launch of panels with 30% castor oil polymers – fully recyclable back to raw materials.

2)Carbon Capture: Each m² of MCM will sequester 0.5kg CO₂ via mineral carbonation tech in development.

Conclusion: Lead or Get Left Behind

From Dubai’s record-breaking skyscrapers to Berlin’s eco-renovations, MCM Flexible Stone Panels are solving the trilemma of beauty, performance, and cost. As Saudi’s Vision 2030 and EU’s Green Deal reshape construction norms, early adopters are already reaping rewards:

1) 23% faster project approvals in Dubai’s DARIYA system

2) 17% higher property valuations with BREEAM Excellent ratings

3) 31% lower lifetime costs vs. conventional cladding